- The MoReCCU project received €560K funding from EIT Manufacturing.

- The system allows reuse of carbonate salt up to 100 times.

- The kick-off meeting took place in January 2023.

- The Slovak University of Technology will design the system, and INEGI will construct it.

Project Overview

UP Catalyst, in collaboration with a consortium of industry experts, is developing a molten salt regeneration technology based on circular economy principles. The MoReCCU project aims to significantly reduce waste and enable the reuse of carbonate salt up to 100 times. This initiative has received €560K funding from EIT Manufacturing under the Regional Innovation Scheme (RIS).

Importance of Raw Materials

As the transition from a fossil fuel-based economy to a carbon-neutral circular economy progresses, sustainable methods for producing and reusing critical raw materials like molten salt are essential. The price of carbonate salt has increased by 260% over the last three years due to its extensive use in energy storage applications.

Technological Innovation

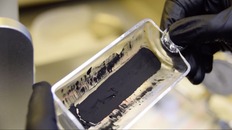

The MoReCCU project focuses on maximizing resource efficiency by reprocessing CO2 to produce carbon nanomaterials and graphite using electrolysis with molten salt as an electrolyte. The technology, known as Molten Salt Carbon Capture and Electrochemical Transformation (MSCC-ET), aims to make carbon nanomaterials and graphite production net negative in terms of CO2 emissions.

Project Execution

A semi-automated system will be constructed to circulate molten salt and remove impurities from the electrolyte mixture, preserving the salt for reuse and improving the quality of the carbon produced. The Slovak University of Technology in Bratislava will design the system, which will be constructed by consortium partner INEGI.

Timeline and Coordination

The kick-off meeting for the MoReCCU project took place in January 2023. UP Catalyst will coordinate the technical and operational activities, while the University of Lleida will conceptualize the system and determine key requirements.