Investment and Production

Talga Resources Ltd will build a demonstration-scale graphene production plant in central Germany, costing under A$1 million. The plant is expected to produce 100-200 tpa of graphene post-commissioning.

Location and Rationale

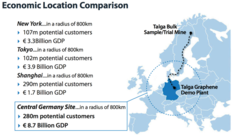

The decision to establish the plant in Germany was driven by significant interest from graphene technologists and end-users. Originally planned for Sweden, the plant was moved to Germany to expedite the production of larger sample sizes. Talga plans to conduct full-scale processing in Sweden in the future.

German Government Support

German government agencies, including the State Development Corporation of Thuringia (LEG) and the Saxony Economic Development Corporation (SED), have offered industrial parks with suitable premises, advantageous permitting, and proximity to Talga's research programs. They also provide operational and investment incentives such as grants, public guarantees, labor incentives, and R&D rebates.

Technical Management

Dr. Georg Hochwimmer has been appointed as Talga’s resident German Technical Manager. He will oversee the establishment of a wholly-owned German subsidiary, Talga Advanced Materials GmbH, and coordinate the plant's design, construction, and commissioning. Dr. Hochwimmer brings experience from BASF and other technology companies in Germany.

Timeline

Pending Swedish trial mining approval in Q2 2015, graphite ore from Sweden will be transported to the German plant for processing starting in Q3 2015. The plant aims to be the first to commercially demonstrate direct ore-to-graphene process technology, facilitating the development of graphene-based products by removing volume and cost barriers.