- Aquafil and Genomatica signed a multi-year agreement to create sustainable caprolactam.

- Caprolactam is a key ingredient for producing 100% sustainable nylon.

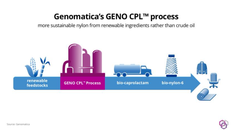

- The GENO CPL™ process uses plant-based renewable ingredients instead of crude oil.

- The global market for caprolactam exceeds five million tons per year.

Partnership for Sustainable Caprolactam

Aquafil and Genomatica have entered a multi-year agreement to develop sustainable caprolactam, a crucial component for producing 100% sustainable nylon. This collaboration aims to create a commercially viable bioprocess, known as Genomatica’s GENO CPL™ process, which utilizes plant-based renewable ingredients instead of traditional crude oil-derived materials.

Environmental and Economic Benefits

Caprolactam is used in various nylon-based products, including carpets and apparel, with a global market exceeding five million tons annually. The GENO CPL™ process offers an environmentally friendly method to produce caprolactam, providing better economics even for smaller-scale plants. This innovation allows licensees and their customers to offer a sustainable bio-based product with performance comparable to nylon made from crude oil-derived caprolactam, without requiring any adjustments in the nylon supply chain.

Opportunities for Industry Collaboration

Genomatica invites other leaders in the nylon value chain to join its bio-nylon program, while Aquafil encourages further collaboration with supply chain partners. By participating in the program, companies ranging from chemical producers and product makers to agriculture companies and major brands can engage, influence priorities, and access Genomatica’s technologies and supply of bio-based chemicals.

Supporting Quotes

Giulio Bonazzi, Chairman and CEO of Aquafil, emphasized the company's commitment to sustainability and the circular economy, highlighting the potential benefits of the new technology for their customers. Christophe Schilling, CEO of Genomatica, noted that this partnership exemplifies how biotechnology can be used to create more sustainable chemical processes, building on Genomatica’s track record of innovation in the industry.