- The plant will be located at Aarhus University’s research facility in Foulum, Denmark.

- The demonstration plant is scheduled to be fully operational in early 2022.

- The project receives funding from the EUDP – Energy Technology Development and Demonstration Program.

- The eSMR Methanol™ technology utilizes biogas and green electricity to produce CO2-neutral methanol.

Project Overview

Haldor Topsoe is set to build a 10 kg/hour methanol plant to demonstrate its eSMR Methanol™ technology, which aims to produce cost-competitive, sustainable methanol from biogas. The plant will be located at Aarhus University’s research facility in Foulum, Denmark, and is funded by the EUDP – Energy Technology Development and Demonstration Program.

Technology and Process

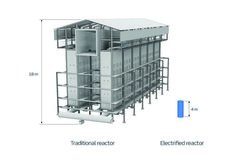

The eSMR Methanol™ technology leverages the full carbon potential of biogas by utilizing the 40% CO2 content, which is typically separated and vented. The process is heated using green electricity from wind turbines or solar panels instead of natural gas, making it CO2-neutral. This technology is about 100 times smaller than traditional units, making it suitable for both decentral biogas sites and large-scale producers.

Operational Timeline

The demonstration plant is expected to be fully operational by early 2022. The goal is to show that sustainable methanol production from biogas can compete with traditional fossil fuel-based methanol in terms of cost.

Economic and Environmental Impact

Currently, biogas in grid quality is more expensive to produce than natural gas. By producing sustainable methanol, biogas producers can significantly increase their production value and compete commercially with fossil-based products. Methanol serves as a clean fuel and an important intermediary in the production of various chemicals and polymers.

Collaborative Effort

The eSMR Methanol™ project is led by Haldor Topsoe and includes partners such as Aarhus University, Sintex A/S, Blue World Technology ApS, Technical University of Denmark, Energinet A/S, Aalborg University, and PlanEnergi. The project aims to transform the chemical industry towards greener processes without increasing production costs.