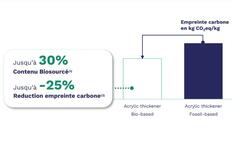

- Acrylic thickeners now have up to 30% bio-based content.

- Carbon footprint reduced by up to 25% compared to standard grades.

- Bio-based products derived mainly from beetroot and sugarcane.

- Products use bio-sourced ethyl acrylate from Carling, France.

Introduction of Bio-Based Additives

Arkema has transitioned its entire line of acrylic thickeners produced in Europe to include bio-based content. This shift aims to maintain the same high performance while introducing up to 30% bio-based content. The initiative also achieves up to a 25% reduction in product carbon footprint compared to standard grades.

Sustainability Goals

The development of these bio-based specialty additives supports the next generation of sustainable coatings and adhesives. This move aligns with the company's commitment to sustainability and helps customers meet their carbon footprint reduction targets. The additives are designed for use in architectural paints, industrial coatings, plasters, renders, adhesives, and sealants, optimizing the rheology of these systems without compromising performance or cost.

Production and Sourcing

The bio-based acrylic thickeners will be marketed under the Rheotech™, Thixol™, and Viscoatex™ brands. These are the first products to utilize the newly announced bio-sourced ethyl acrylate, produced at Arkema's acrylic monomer facility in Carling, France. The bio-based content is derived mainly from biomass sources such as beetroot and sugarcane, following the EN16640 standard for carbon ratio breakdown.

Environmental Impact

The product carbon footprint (PCF) is calculated from cradle-to-gate, including biogenic absorption, in accordance with ISO standards 14040, 14044, and 14067. This approach ensures a comprehensive assessment of the environmental impact, further supporting the company's sustainability objectives across the value chain.