- Supported by EU's Horizon 2020 and Swiss government, the project aims to demonstrate Power-to-Gas technology.

- The plant will convert CO2 and H2 into synthetic natural gas using archaea as biocatalysts.

- The modular plant design allows for pre-fabrication and scalability, with commissioning set for mid-2018.

Project Overview

CALORIC has secured an international contract to engineer and construct a biomethanation pilot and demonstration plant in Solothurn, Switzerland. This facility will utilize microorganisms as biocatalysts to methanate carbon dioxide and hydrogen.

Funding and Objectives

The project is backed by the European Union’s Horizon 2020 research and innovation program and the Swiss government. It is part of the STORE & GO initiative, which aims to demonstrate the technical and economic feasibility of a new Power-to-Gas (PtG) technology on an industrial scale. This technology is based on a patented biocatalyst solution developed by Electrochaea GmbH.

Technical Details

The biomethanation process will convert excess renewable energy into synthetic natural gas (SNG) by reacting hydrogen and carbon dioxide, catalyzed by single-celled microorganisms known as archaea. The resulting biomethane will be of pipeline-grade quality, suitable for injection into the gas grid.

Design and Construction

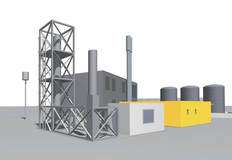

CALORIC will design a skid-mounted processing plant, incorporating a vertical bioreactor and a control room container, all within a compact area provided by Regio Energie Solothurn. The plant is designed for flexible operation across a range of capacities, emphasizing modularization and standardization to allow for future scalability.

Implementation Timeline

The modular design enables pre-fabrication of skids at CALORIC’s factory, including fabrication, assembly, painting, cabling, and component testing. The plant is scheduled for onsite commissioning under CALORIC’s supervision by mid-2018.