- GreenIron's Sandviken plant will use green hydrogen for metal production.

- Deliveries from Norwegian Hydrogen to Sandviken will start shortly.

- GreenIron plans to scale up production in 2025.

- The process uses hydrogen to reduce iron oxides, producing iron and water.

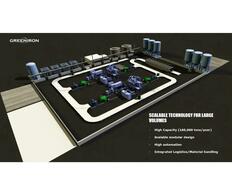

GreenIron's Sandviken Plant

GreenIron is set to commence operations at its green metals production facility in Sandviken, Sweden. The plant will utilize a patented zero-emissions technology, employing green hydrogen as a reducing agent. In this process, hydrogen reacts with iron oxides to produce metallic iron and water, ensuring an environmentally friendly production method.

Partnership with Norwegian Hydrogen

Norwegian Hydrogen will supply the green hydrogen needed for GreenIron's operations. The company has recently inaugurated its first production plant in Norway, and deliveries to Sandviken are scheduled to begin shortly. This collaboration is crucial for GreenIron as it secures the supply chain necessary for the plant's commercial production and future expansion.

Production Scale-Up

As GreenIron plans to scale up its production in 2025, the demand for hydrogen will increase significantly. This will necessitate additional and dedicated hydrogen production capacity to meet the growing requirements. The partnership with Norwegian Hydrogen is a strategic move to ensure a steady supply of green hydrogen as GreenIron expands its operations.

Industrial Application of Green Hydrogen

The agreement between GreenIron and Norwegian Hydrogen highlights the potential of green hydrogen in industrial applications, particularly in metals production. By using hydrogen-based technology, GreenIron aims to minimize CO2 emissions and contribute to sustainable industrial practices. This collaboration underscores the business potential of green hydrogen as a viable alternative in the industry.