Production Launch

BASF has commenced commercial production of lithium iron phosphate (LFP) cathode materials at a new plant in Weimar, Germany. The facility has a capacity of 3,000 metric tons per year and utilizes LFP precursors produced at BASF's headquarters in Ludwigshafen.

Operational Management

IBU-Tec, a specialist in rotary kiln technology, is responsible for the operations at the Weimar plant, working under the supervision and full operational control of BASF.

Product Applications

The LFP materials produced are used in advanced lithium-ion batteries (LiBs), offering enhanced power and safety features. This addition complements BASF's existing portfolio, which includes Nickel Cobalt Manganese (NCM) cathode materials produced in Elyria, Ohio.

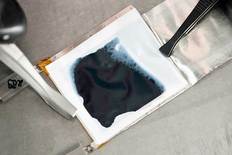

Proprietary Process

BASF's HED™ LFP is manufactured using a proprietary process designed to ensure superior performance and consistent quality across batches.

Licensing Agreements

BASF holds a long-term global license for LFP battery materials technology from LiFePO4+C Licensing AG, an affiliate of Clariant AG, which possesses a leading global patent portfolio in LFP technology. Additionally, BASF is licensed by Argonne National Laboratory to produce and sell advanced NCM materials.

Strategic Goals

These developments are part of BASF's broader strategy to build a comprehensive portfolio of battery materials technology, aiming to become a leading provider of functional materials and components for cell and battery manufacturers worldwide.