- Velocys reduces microFTL™ technology capital costs by over 30% through standardisation and efficiencies.

- Altalto project in the UK converts waste to low-carbon aviation fuel, supported by the UK Department for Transport.

- NovaSAF 1 in Uruguay uses biogas to produce SAF, with a long-term offtake agreement with Trafigura.

- Both projects are moving toward final investment decisions.

Cost Reduction Achieved

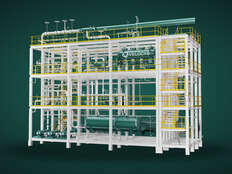

Velocys has implemented standardisation, manufacturing, and delivery efficiencies that reduce capital costs for its microFTL™ technology by more than 30%. These improvements are applied to two key Fischer–Tropsch Sustainable Aviation Fuel (SAF) projects: Altalto in the UK and NovaSAF 1 in Uruguay.

Altalto Project

Located in the Humber region, the Altalto project is advancing toward engineering with support from the UK Department for Transport’s Advanced Fuels Fund. It aims to convert residual household and commercial waste into low-carbon aviation fuel, aligning with the UK’s SAF and decarbonisation goals.

NovaSAF 1 Project

Developed by Syzygy Plasmonics, NovaSAF 1 uses renewable-powered reforming and Velocys FT synthesis to produce SAF from biogas. The project has reached a significant milestone with a long-term offtake agreement signed with Trafigura and is progressing toward a final investment decision.

Strategic Advancements

Velocys has re-examined its technology offering across active projects, working with strategic manufacturing partners to streamline reactor fabrication, modularisation, and delivery. These optimisations maintain performance and technology readiness while significantly lowering capital expenditure.