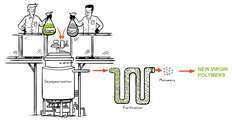

- CARBIOS has produced virgin PET from terephthalic acid via enzymatic hydrolysis of post-consumer bottles.

- The synthesis of PET oligomers from this process was previously demonstrated.

- The next goal is to prove this virgin PET's suitability for new bottle production.

- This innovation supports a circular economy for PET plastic products.

Introduction

CARBIOS has announced a significant advancement in bioplasturgy with the production of virgin PET from terephthalic acid derived from its biorecycling process of post-consumer PET plastic bottles.

Previous Achievements

Previously, CARBIOS successfully synthesized PET oligomers from terephthalic acid obtained through its biorecycling process. This was a crucial initial step towards producing PET.

Current Milestone

The company has now completed the synthesis of virgin PET from these oligomers, confirming the potential of its technology for recycling plastic bottle waste into virgin PET polymers.

Future Goals

CARBIOS aims to demonstrate that this virgin PET is suitable for producing new bottles, thereby contributing to a circular economy for PET plastic products.

Expert Opinions

Alain Marty, Chief Scientific Officer of CARBIOS, highlighted the achievement of demonstrating that enzymatic depolymerization of PET bottles enables the return to virgin PET. Jacqueline Lecourtier, President of CARBIOS Scientific Committee, emphasized the innovation's potential for efficient and environmentally friendly recycling of plastic waste.