- WACKER starts serial production of NEXIPAL® Sense laminates using a roll-to-roll process.

- The laminates are made of stretchable insulating and conductive silicone rubber films.

- Production is near Burghausen, Germany, using electricity from WACKER's photovoltaic system.

- NEXIPAL® Act, an actuator version, is planned for serial production in 2026.

Introduction

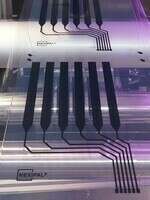

WACKER has initiated the serial production of NEXIPAL® Sense sensor laminates, marking a significant advancement in flexible printed electronics. This development will be showcased at the K 2025 trade fair in Düsseldorf, Germany.

Manufacturing Process

The laminates are produced using a fully automated roll-to-roll manufacturing process. They consist of highly stretchable insulating and electrically conductive silicone rubber films, forming a flexible and stretchable capacitor.

Applications and Features

NEXIPAL® Sense laminates are suitable for applications in medical technology, robotics, and sports. They offer precise sensor signals by changing electrical capacitance in response to pressure or flex movements. The laminates are characterized by their elasticity, dimensional stability, and toughness, and are biocompatible, UV-resistant, and temperature-resistant.

Production Details

Production takes place near Burghausen, Germany, utilizing electricity from WACKER's photovoltaic system. The process is environmentally friendly, avoiding rare earths, solvents, and heavy metals, and operates at low temperatures.

Future Developments

WACKER plans to introduce NEXIPAL® Act, an actuator version of the laminate, into serial production in 2026. These laminates will create precise, smooth, and silent movements when an electrical voltage is applied, expanding their use in human-machine communication applications.