- AKM's thin-film Hall elements were commercialized in 1983.

- The technology uses a thin-film indium antimonide (InSb) layer.

- Over 50 billion Hall sensor units have been shipped worldwide.

- AKM's Hall elements are used in brushless motors and energy-efficient equipment.

Introduction

Asahi Kasei Microdevices Corporation (AKM) has been recognized by the IEEE for its commercialization of thin-film Hall elements, a significant milestone in electrical and electronic engineering.

Technological Advancements

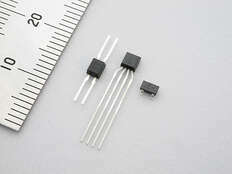

Launched in 1983, AKM's HW Series marked a breakthrough in mass-producing magnetic sensors using thin-film Hall elements. These elements have become a standard in electronic devices worldwide.

Innovations and Impact

Early thin-film Hall elements faced sensitivity and reliability challenges. AKM addressed these by using a thin-film indium antimonide (InSb) layer and a three-layer electrode structure, enhancing thermal stability and durability. This led to the industrialization of the technology, with over 50 billion units shipped globally.

Applications and Future Developments

AKM's Hall elements are widely used in brushless motors, contributing to the miniaturization of IT infrastructure and consumer electronics. They also aid in energy conservation by improving the efficiency of HVAC and refrigeration equipment. AKM is expanding magnetic sensing into new areas like precision position detection and current sensing, enhancing smartphone cameras and electric vehicle performance.