- HYBRIT receives €143 million from the EU Innovation Fund for hydrogen-based iron and steelmaking.

- The project aims to produce 1.35 million tonnes of hydrogen-reduced iron annually, reducing CO2 emissions by 14.3 million tonnes over 10 years.

- A new facility with 500 MW fossil-free electrolysis will be established in Gällivare, Sweden.

- SSAB will replace blast furnaces with an electric furnace in Oxelösund by 2030.

EU Innovation Fund Support

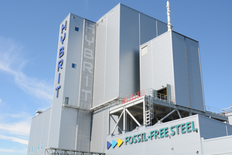

The HYBRIT initiative, driven by Vattenfall, SSAB, and LKAB, has received €143 million from the European Union's Innovation Fund. This funding is part of a larger €1.1 billion investment in seven projects aimed at decarbonizing various industries, including chemicals, steel, cement, refineries, and power and heat.

Project Goals and Impact

HYBRIT aims to demonstrate a complete value chain for hydrogen-based iron and steelmaking, from mining to producing fossil-free steel. The project will produce approximately 1.35 million tonnes of hydrogen-reduced iron annually, which will be used to produce crude steel, accounting for about 25% of Sweden's total steel production. This initiative is expected to reduce greenhouse gas emissions by 14.3 million tonnes of CO2 over the first 10 years of operation.

Key Developments

The project includes the establishment of a new facility in Gällivare, Sweden, featuring 500 MW fossil-free electrolysis for hydrogen production. Additionally, SSAB will replace its blast furnaces with an electric furnace in Oxelösund. The grant agreement for the project was signed at an official ceremony in Stockholm on April 1st.

Technological Advancements

HYBRIT will demonstrate the technical and commercial viability of hydrogen direct reduction, electric melting of hydrogen-based direct reduced iron, and fossil-free DR-pellets production. These advancements are crucial for the transition to fossil-free steelmaking and for meeting EU climate targets.