- Researchers developed a catalyst system using CO₂ and green hydrogen.

- The process converts olefins into esters, replacing carbon monoxide.

- Transition metals iridium and palladium are used in the catalyst.

- The system shows high selectivity for linear products.

Introduction

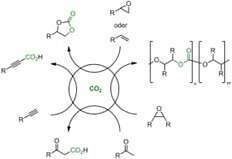

Researchers from the Leibniz Institute for Catalysis, Ruhr University Bochum, and Evonik Oxeno have developed a catalyst system that uses carbon dioxide (CO₂) as a raw material for the chemical industry. This innovation supports sustainable production of key products like fragrances and plastic building blocks.

Carbonylation Process

Carbonylation, a central chemical manufacturing process, converts olefins into esters or acids using carbon monoxide. These substances are crucial for producing everyday products, including basic chemicals like methyl methacrylate and specialty chemicals such as valeric acid methyl ester.

New Catalyst System

The new bimetallic catalyst system replaces toxic carbon monoxide with CO₂ and green hydrogen. It uses transition metals iridium and palladium, along with an industrial phosphine ligand, to directly convert olefins into esters. The system is highly selective for linear products, which are valuable in industrial applications.

Impact and Perspective

This development highlights the potential of CO₂ as a valuable resource rather than waste, contributing to the defossilization of the chemical industry. The research opens new possibilities for producing industrially relevant chemicals from CO₂ and green hydrogen in a resource-efficient manner.