Capacity Expansion

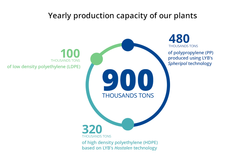

Basell Orlen Polyolefins Sp. z o.o. (BOP) has completed a development project on its Spheripol installation in Plock, Poland, increasing its polypropylene (PP) manufacturing capacity by 20% to 480,000 tons annually. This expansion brings the company's total polyolefin capacity to 900,000 tons per year, including 320,000 tons of high-density polyethylene (HDPE) and 100,000 tons of low-density polyethylene (LDPE).

Investment and Infrastructure

The increase in PP capacity is linked to the Metathesis installation investment by one of BOP's shareholders, Polski Koncern Naftowy ORLEN SA. This project also involved improvements to the BOP Logistics Platform to ensure sufficient storage capacity, making the Spheripol installation the largest PP production line in Europe.

Production History

Construction of the Spheripol installation in Plock began in 2003 and was completed in 2005. Since then, BOP has produced nearly 4 million tons of PP. The company manufactures various PP grades, including homo, raco, and heco-polymers, suitable for diverse applications such as packaging, textiles, automotive parts, and pipes.

Product Characteristics

PP grades produced in Plock using Spheripol technology are known for their high cleanliness, consistent physical properties, and good processability. These versatile products are used in a wide range of consumer goods, meeting the growing demand for bulk supply in the proximity of the plant.