- The new production line at Mannheim started in May 2018.

- The investment volume is in the single-digit-million-euro range.

- The production line synthesizes dimercaptothiadiazole (DMTD) derivatives.

- DMTD derivatives are used as multifunctional additives in lubricants.

New Production Line

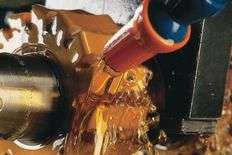

Specialty chemicals company LANXESS has launched a new production line at its Mannheim site for synthesizing dimercaptothiadiazole (DMTD) derivatives. This new line, operational since May 2018, doubles the annual production capacity of these specialty additives. The investment for this expansion is in the single-digit-million-euro range.

Meeting Increased Demand

The investment addresses the rising customer demand for high-quality lubricant additives. The new plant not only meets existing customer requirements but also aims to attract new customers and develop comprehensive package solutions for a rapidly growing market.

Applications of DMTD Derivatives

DMTD derivatives serve as multifunctional additives in lubricants, primarily providing corrosion protection for steel alloys containing nonferrous metals like copper, nickel, or cobalt. These additives prevent the leaching of metal ions, protect metal surfaces from aggressive chemicals, and ensure the longevity of steel alloys. They also act as lubricants under extreme conditions and high pressures, making them valuable as extreme pressure additives. Additionally, they absorb aggressive chemical breakdown products in lubricants, preventing long-term material damage. Key applications include industrial oils, greases, and metalworking fluids.

Manufacturing and Quality

Under the Additin brand, LANXESS supplies DMTD derivatives globally, which are also used in its additive packages. A specialized manufacturing process ensures optimal composition, resulting in excellent and consistent performance. Compared to competitor products, these additives are noted for their stable quality, mild odor, and clear appearance. Production is exclusively carried out at the Mannheim site.